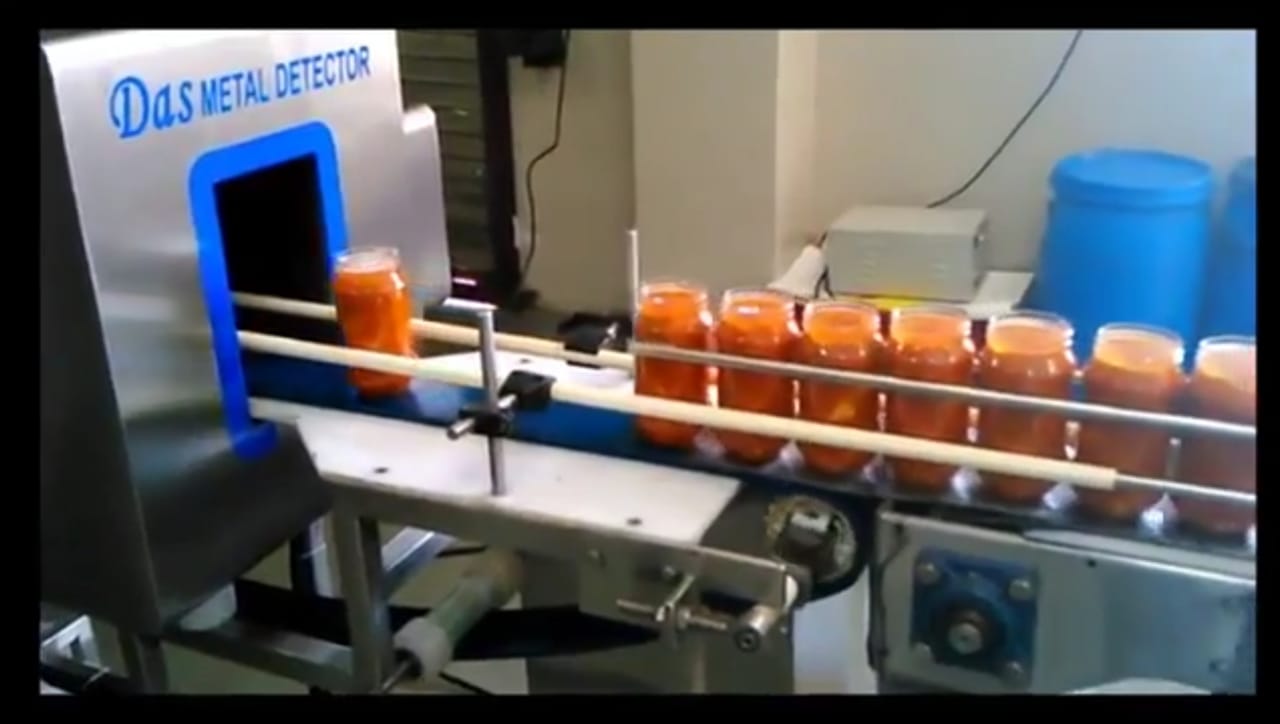

Ensure the safety and quality of your bottled products with our Conveyor Metal Detector with Rejection, specifically designed to detect and eliminate metal contaminants in plastic and glass bottles. Metal contamination, whether from production equipment, packaging materials, or foreign objects, can compromise the integrity of your products, harm your customers, and damage your brand's reputation. This advanced metal detection system provides a reliable solution by identifying and rejecting metal contaminants before they reach consumers. In the beverage industry, metal fragments in plastic and glass bottles can arise from various sources, including machinery wear and tear, metal packaging, or accidental introduction during handling. Even the smallest piece of metal can lead to costly recalls, regulatory fines, and consumer complaints. Our Conveyor Metal Detector with Rejection ensures that your products meet the highest safety standards by efficiently detecting and removing any metal contaminants, offering peace of mind for both producers and consumers. Equipped with high-sensitivity detection technology, this system can identify ferrous, non-ferrous, and stainless steel metals, even in trace amounts. The integrated rejection mechanism ensures that contaminated bottles are automatically diverted from the production line, preventing any defective products from reaching the packaging stage. This ensures that your production process remains uninterrupted while maintaining quality and safety.

Send Message