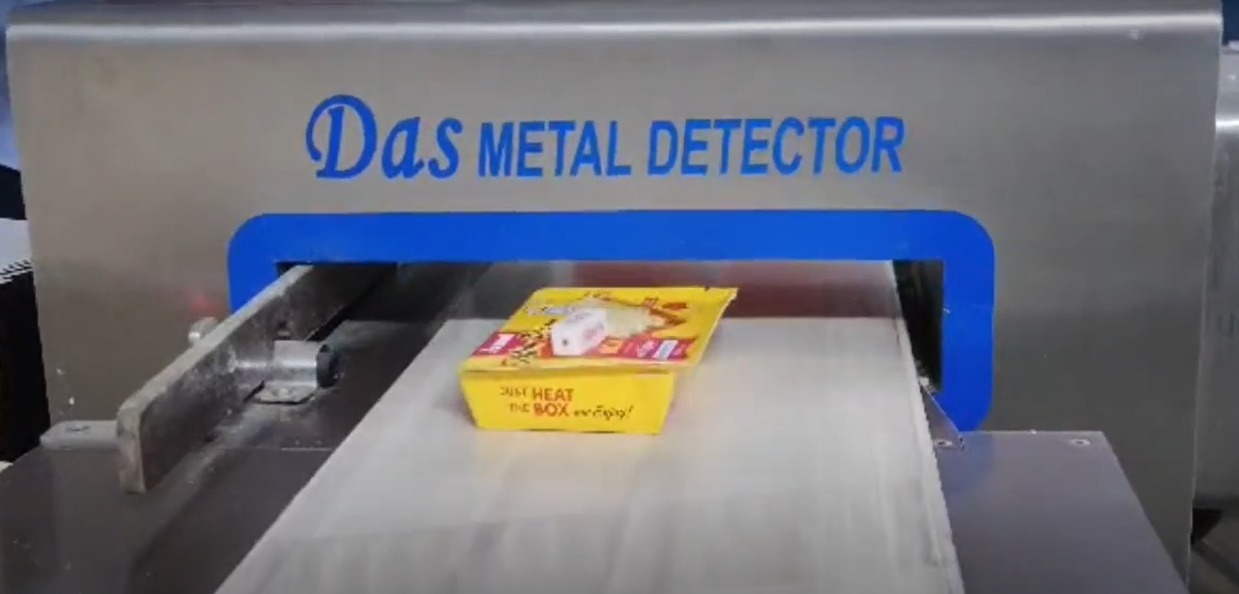

Ensure the safety and quality of your ice cream products with our Conveyor Metal Detector, specifically designed to detect and remove metal contaminants from ice cream packs and bars. Metal contamination, whether from packaging, production machinery, or handling, can pose serious risks to both consumer health and your brand's reputation. Our advanced system is engineered to provide reliable protection against metal fragments, ensuring that every pack of ice cream that reaches your customers is free from foreign contaminants. In the ice cream industry, metal contaminants such as ferrous, non-ferrous, and stainless steel can find their way into products during manufacturing or packaging processes. Even the smallest piece of metal can lead to costly product recalls, regulatory fines, and damage to customer trust. Our Conveyor Metal Detector offers an effective solution by identifying and removing these contaminants with high precision, helping you maintain the highest food safety standards. The metal detector is equipped with advanced technology to detect a wide range of metal types, including the ability to detect even the smallest fragments of metal, ensuring thorough inspection. This makes it ideal for a variety of ice cream products, from individually wrapped bars to large ice cream tubs. The system integrates seamlessly into your production line with minimal disruption, allowing continuous, efficient operation.

Send Message