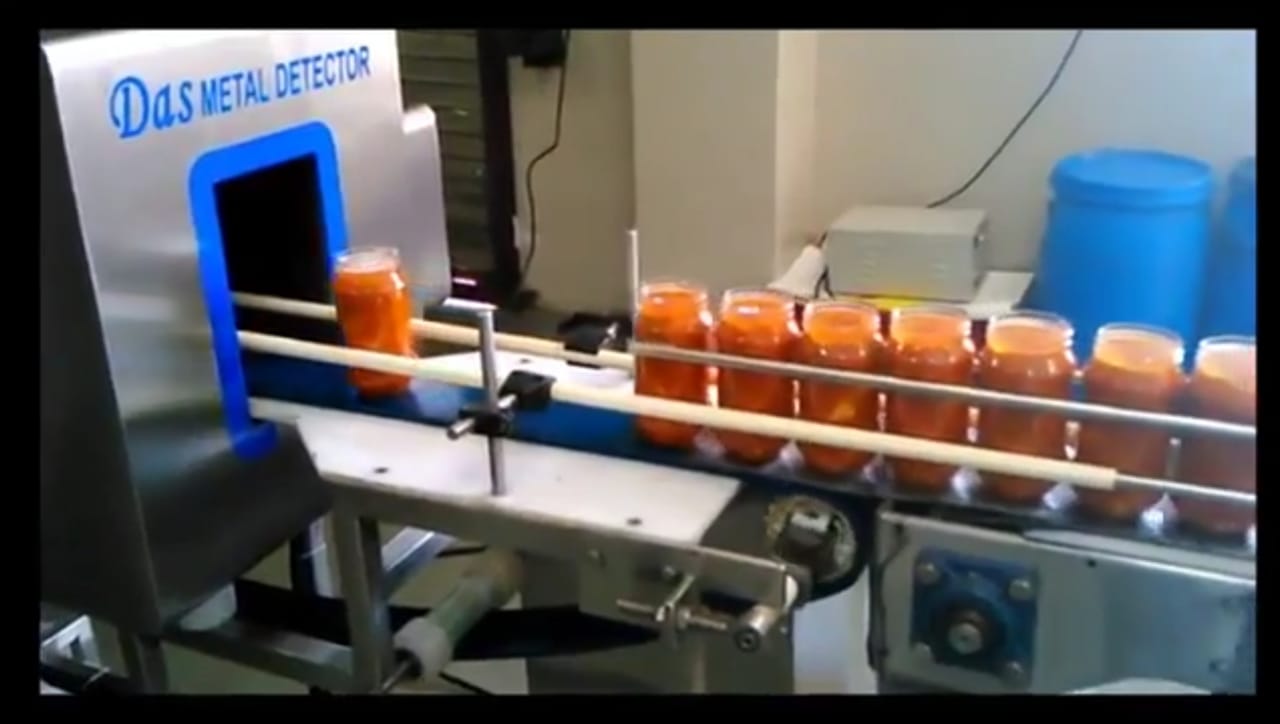

Ensure the safety and quality of your cookies and biscuits with our Conveyor Metal Detector, designed specifically to detect and eliminate metal contaminants in baked goods. Metal contamination can arise during production, packaging, or handling, posing serious risks to consumer health and your brand’s reputation. Our advanced metal detection system offers a reliable solution to identify and remove metal fragments, ensuring your products meet the highest food safety standards. In the cookie and biscuit industry, metal contaminants such as ferrous, non-ferrous, and stainless steel can come from machinery, packaging materials, or foreign objects during production. Even the smallest piece of metal can lead to costly product recalls, consumer complaints, and regulatory issues. Our Conveyor Metal Detector is engineered to detect and reject these contaminants with high precision, protecting your products from any potential risk. Equipped with cutting-edge detection technology, this metal detector is sensitive enough to identify even the smallest metal particles in your cookies and biscuits. It seamlessly integrates into your existing production line, providing continuous, efficient operation without interrupting the flow of your products. From soft cookies to crunchy biscuits, it offers reliable protection across a wide variety of baked goods.

Send Message